Whether you run a small retail business or a complex wholesale operation, it’s critical to understand what “safety stock” is and how much to keep. This is because it is essential to maintain adequate inventory levels at this stage. Unfortunately, figuring that out can be challenging.

The good news is that learning more about safety stock and the equations you can use to calculate it will better position you to ensure you’re maintaining an affordable and appropriate amount. Even in emergencies or stockouts, you can have peace of mind knowing that unforeseen matters won’t disrupt your business.

In this post, we’ll explain what safety stock is and its purpose. Then we’ll explain how much of it you should keep to ensure smooth business operations. Let’s get started!

What Is Safety Stock?

Safety stock is a type of inventory that business owners keep to protect their businesses against the risk of out-of-stock situations. This could be due to a wide range of unfortunate circumstances, including:

- Inaccurate or excess demand

- Supplier delays

- Late placed orders

- Supply chain disruptions

It’s important to note the difference between safety stock vs. reorder point.

Safety stock is the amount of inventory you keep in stock to shield against unpredictable demand or supply chain changes and disruptions. It is the difference between the reorder point and the current inventory level. In addition, the reorder point is the level at which you would need to order more inventory.

Your customer demand rate and lead time determine your safety stock level. You can calculate it by dividing the customer demand rate by the lead time. For example, if you have a customer demand rate of 10 and a lead time of two, your safety stock level would be five units.

What Is the Purpose Of Safety Stock?

The primary purpose of safety stock is to prevent you from running out of inventory. Safety stock covers the time between a reorder point and when the inventory level reaches zero.

It’s essential because, without safety stock, you may end up irritating and upsetting your customers when the item(s) they want aren’t available.

But, on the other hand, you don’t want to have too much safety stock. When this is the case, you might end up with products going bad or facing excessively high storage costs.

However, you can avoid both of these worst-case scenarios with the right amount of safety stock. In addition, you’ll be able to comfortably operate your business knowing you have a healthy amount of stock to replenish inventory at the last minute if or when necessary.

How Much Safety Stock Should Your Company Keep?

Now that we understand more about what safety stock is and its purpose, you might be wondering how to calculate it, so you know what’s appropriate for your company to keep.

There are a few ways that you can calculate safety stock. The primary safety stock formula multiplies the number of products sold daily by the number of days’ worth of safety stock.

Let’s say you sell 400 units per day, and you want to ensure that you have one week’s worth of safety stock. You could multiply 400 by seven, equating to a safety stock of 2,800 units.

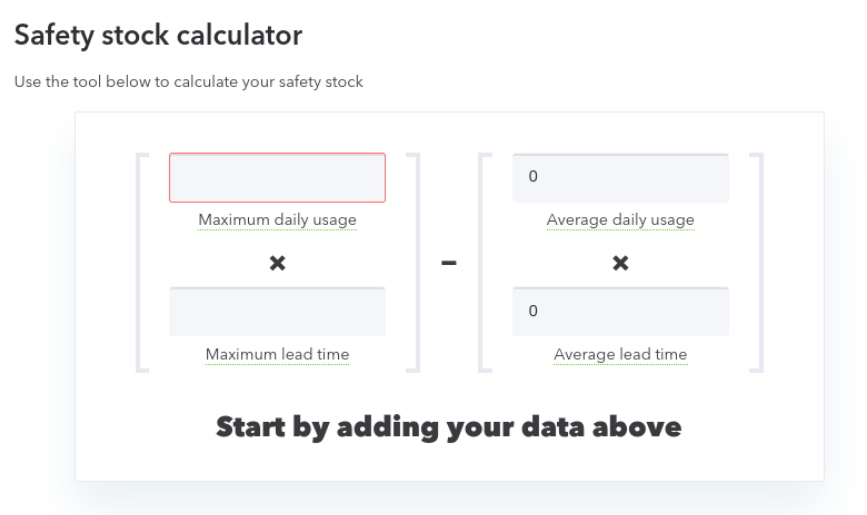

To make calculating your safety stock levels easier, you could use an online calculator tool such as the one provided by Intuit QuickBooks:

However, you can also use more sophisticated formulas that account for different variables, such as demand and lead time. For example, you could use the following formula based on the average demand:

Safety Stock = Average Demand X Lead Time + Safety Margin

Another option is to approach it based on the Economic Order Quantity (EOQ). This refers to the ideal amount of stock you should purchase to keep inventory costs low:

Safety Stock = EOQ x Lead Time + Safety Margin

The best formula method to calculate your safety stock depends on many factors. These factors include your supplier’s lead times, current and forecasted demand, and how quickly your inventory moves.

We recommend starting with the basic formula to get a general idea. Then you can always calculate other equations to get a more precise safety stock level based on specific variables.

Conclusion

As a business owner, keeping enough inventory on hand to meet customer demand is of utmost importance. Therefore, it’s crucial to calculate your safety stock to ensure items are available even during times of disaster, delays, or disruptions.

In this article, everything you need to know about safety stocks and how much you need to keep. We divided these topics into:

- What Is Safety Stock?

- What Is the Purpose Of Safety Stock?

- How Much Safety Stock Should Your Company Keep?

Do you have any questions about safety stock? Let us know in the comments section below!